ZHGV - transfer system for warm forming and forging

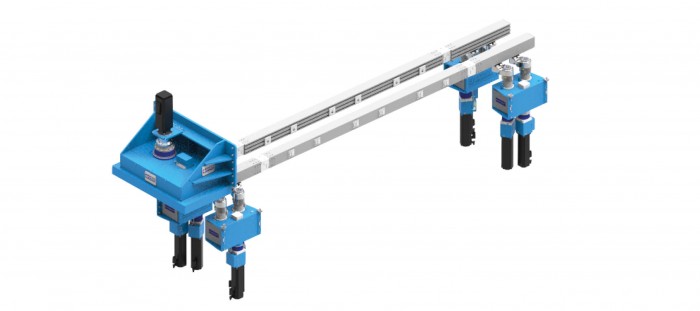

The patented swing arm NC transfer unit ZHGV or ZGV is one of the established systems and enables correspondingly higher stroke rates due to its low-backlash axes. Due to the fully enclosed drive units, this series is predestined for semi-hot and hot forming and forging processes.The different sizes allow mounting on various forming presses with a maximum bolster length of 4500 mm.The gripper rail profiles can be designed as fixed or changeable rails. Depending on the products to be transported and the installation situation, a variety of profiles up to 200 x 200 mm can be chosen.With its high flexibility and endless integration possibilities, the ZGV transfer unit can be used with virtually any transfer press.The ZHGV/ZGV series is the transfer system of choice regardless whether you have a new press in mind or want to use it as retrofit system to boost the performance of your existing system.The fully programmable transfer system is designed as ZHGV for 3D use and as ZGV for 2D use without lifting stroke.Find our more about the technology and your benefits in our product flyer.DSTG

The patented DSTG/DSG double swing-arm NC-transfer system are one of the most recent developments, and thanks to their rigid design, higher stroke rates are possible. The different sizes allow the transfer system to be used on various forming presses with a maximum bolster length of 5500 mm.The gripper rail profiles can be designed either as continuous or exchangeable rails. Depending on the products to be transported and the installation situation, a profile of up to 200 x 200 mm can be freely selected.

The open design and high flexibility enables both transfer systems to be used on various presses in the case of a new purchase or upgrades and retrofits.The transfer systems are designed for 2D as well as 3D applications with lifting stroke.You can find technical data as well as the possible options and operation modes in the product flyer.

ZHGV - transfer system for warm forming and forging

ZHGV - transfer system for warm forming and forging

DSTG

DSTG